PLAN

Our custom signage creation process is built around our experience working with large institutional and municipal and ministries. With our powerful database and mapping approach we can complete full surveys and create large scale plans for the development of interior and exterior signs. We can also analyze the regulatory environment including code and regulatory approvals.

- Evaluate Location for Access

- Measure Sign Location

- Assess Installation Needs

- Submit Data to Project Management, Design and Engineering for Review

DESIGN

We manage the complete sign creation process, or we can support architects and designers to facilitate their design vision. Starting with conceptual design and visualization we can develop a complete design vocabulary as well as cohesive identity guidelines including type, color and materials. Union plastics also has the unparalleled ability to test design through color samples, mockups and legibility testing.

- Review Survey Information

- Check Local Authority Requirements

- Analyze Existing Site Conditions

- Produce Aesthetic Design for Submittal to Client

- Produce Amendments, Resubmit to Project Manager for Client Approval

- On Approval, Submit to Engineering

ENGINEER

Throughout the design process we utilize both durability and a value engineering approach built around the programmatic needs of each project. This includes testing of mockups for materials and technology as well as documentation through shop drawings, engineered stamped drawings and guidelines.

- Produce Necessary Cut Files for Production

- Ensure Survey Information is Correctly Assimilated into Design

- Produce All Installation Templates

- Quality Check and Submission into Production

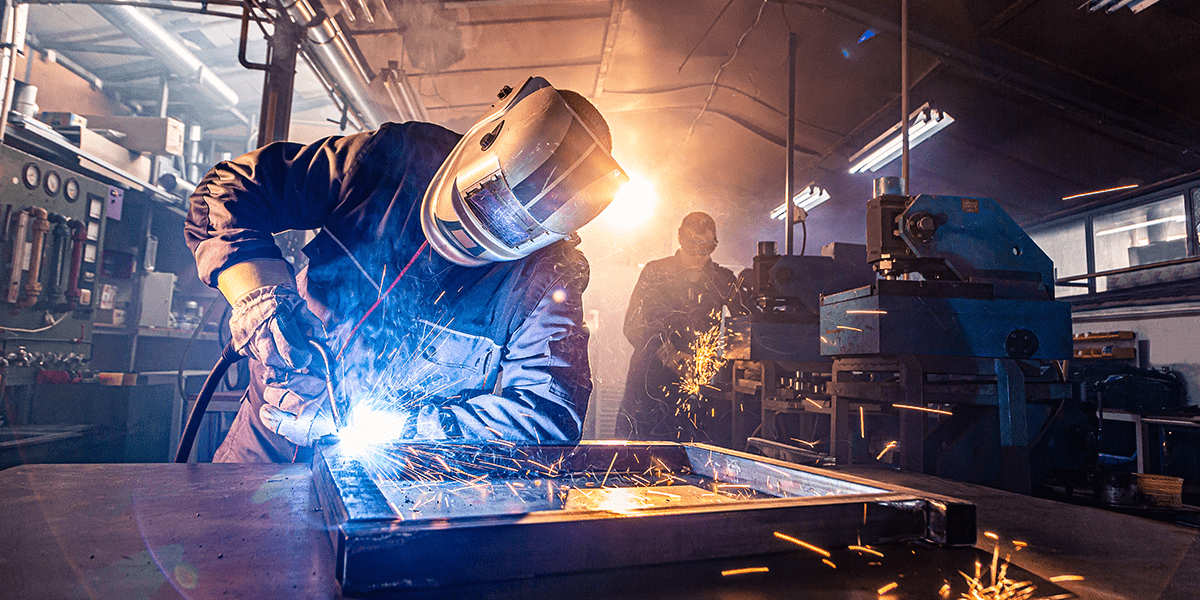

MANUFACTURE

Our manufacturing approach is built around our experience in the creation of architectural and modular products for large wayfinding and identity programs and signages. We focus on excellence in the details, from materials to lighting elements, to manufacturing to packaging and shipment. Our extensive planning and project management ensure the best results for small- and large-scale challenges.

- Multi-stepped Review and Control Process

- Only Quality Sign Materials Used in All Applications

- Fully Integrated Production Management Process

- Inspect Final Products Prior to Shipment or delivery

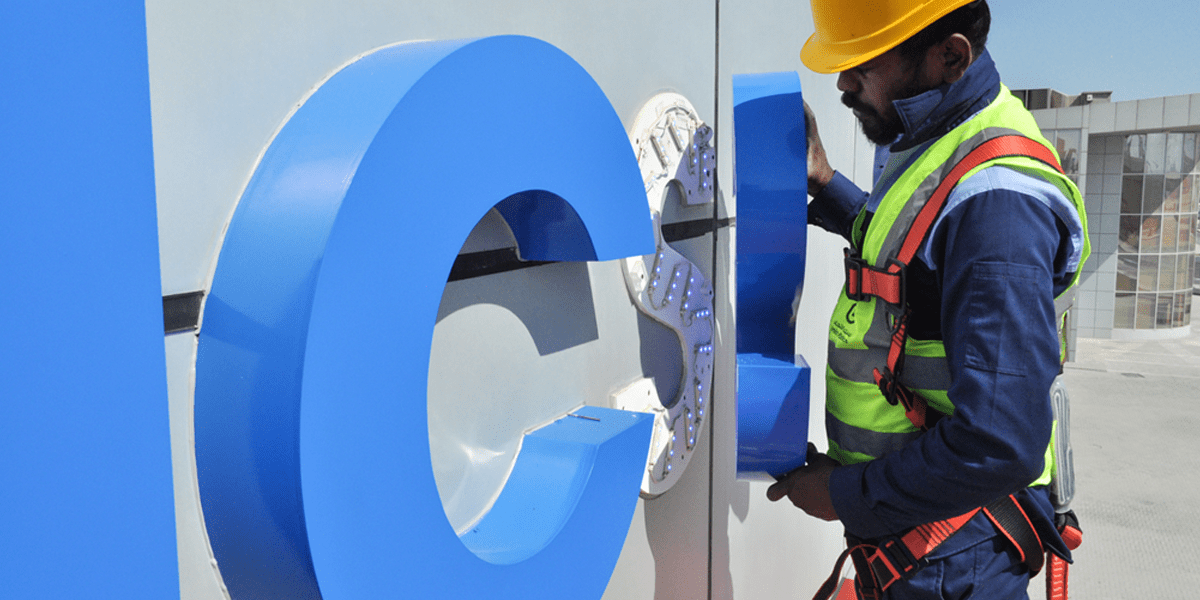

INSTALL

Because of experience managing national and international projects we have the ability to arrange an installation team that can easily adapt to landmark or architectural venues. This includes experts in areas ranging from foundations to electrical work. We can also successfully manage the installation approval process for rollouts that require outside installation support.

- Clear Communication with Customer Prior to Installation

- Site Visit with Representative

- Detailed Surveying Conducted On a Site-by-site Basis

- Post-Installation Check, Photo Record and Completion Report Supplied On Each Completed Project